Wallace A. “Mike” Kulczyk enjoyed the challenges of building and flying scale model jets. In the mid-to-late 1960s the biggest challenge involved was simulating the jet engine with ducted fan systems. Before these systems were commercially available many modelers, including Mike, pioneered “fans in a can.”

Ducted fan systems placed glow engines inside a close-fitting shroud, often made of a tin food can, and used multi-bladed fans to accelerate air through a nozzle – basically an air pump. Figuring out the size, angle of blades and materials to build the units required research and ingenuity. Mike shared his knowledge in an article published in American Aircraft Modeler, February 1971 where he explained the two methods of constructing the multi-bladed fans, as well as the importance of finding the right size container (his recommendation was to visit the grocery store with a ruler).

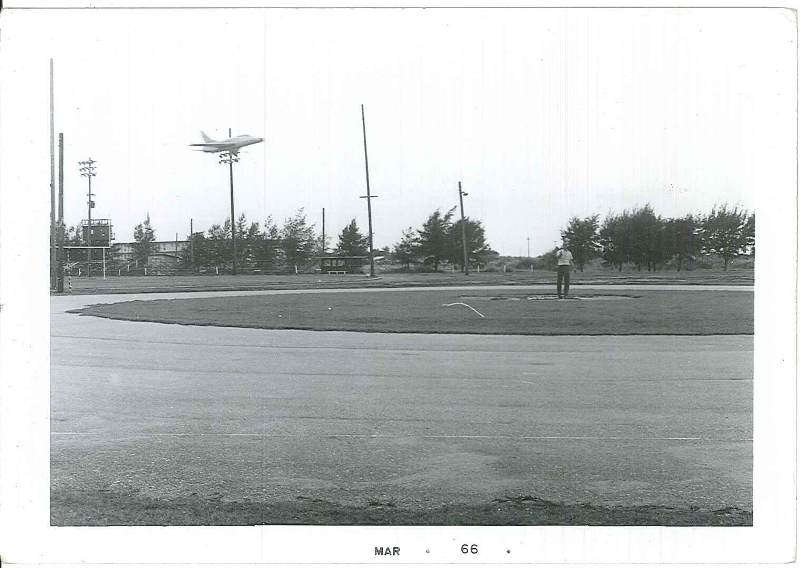

Mike’s hard work certainly paid off, if these pictures of his CL F-100 Super Sabre are anything to go by.

Interested in making your own fan in a can? This drawing explains the main points, and feel free to email Maria at mariav@modelaircraft.org to request a copy of his 1971 article (article reprints are $4.00.) There’s also several books about ducted fan units and model jets in the museum’s library.

Five of Mike’s ducted fan units are in the museum’s collection, as well as several of his flow straighteners and impellers. The items were donated by Richard Maus, In Memory of Lt. Col. Wallace “Mike” Kulczyk and In Memory of Lt. Col. Wallace “Mike” Kulczyk by his children.

—————————————————————————

For more information on the National Model Aviation Museum, including our location, hours and admission fees visit: www.modelaircraft.org/museum

Recent Comments